Unleashing Potential: Optimizing Operations With Modern Sheet Metal Machinery

In today's rapidly evolving industrial landscape, the efficiency and precision of operations are paramount for staying competitive. Among the many industries that rely heavily on efficient manufacturing processes, sheet metal fabrication stands out as a cornerstone of modern construction, automotive, aerospace, and many other sectors. The advent of modern sheet metal machinery has revolutionized the way sheet metal is processed, opening up new horizons of possibilities and efficiencies for businesses worldwide.

Evolution of Sheet Metal Machinery

The history of sheet metal machinery is a testament to human ingenuity and the relentless pursuit of efficiency. From rudimentary manual tools to complex computer-controlled systems, the evolution of sheet metal machinery has been marked by a constant drive towards automation, accuracy, and speed.

Early Tools and Techniques

Centuries ago, craftsmen relied on basic hand tools such as hammers, anvils, and shears to shape and manipulate sheet metal. These early methods were labor-intensive and often limited in their precision and repeatability. However, they laid the groundwork for more sophisticated techniques to come.

Industrial Revolution and Mass Production

The advent of the Industrial Revolution brought about significant advancements in sheet metal processing. Steam-powered machinery enabled mass production on a scale never before seen, leading to the widespread adoption of sheet metal in various industries. Mechanical presses, powered shears, and roll forming machines revolutionized the manufacturing landscape, making sheet metal products more accessible and affordable than ever.

Introduction of CNC Technology

The latter half of the 20th century saw the rise of computer numerical control (CNC) technology, which transformed sheet metal fabrication yet again. CNC machines allowed for greater precision, repeatability, and automation in the production process. Manufacturers could now program complex cutting, bending, and forming operations with unprecedented accuracy, paving the way for a new era of efficiency and productivity.

Modern Sheet Metal Machinery: A Technological Marvel

Today, modern sheet metal machinery represents the pinnacle of manufacturing technology. These cutting-edge machines leverage advanced automation, robotics, and software integration to streamline operations and optimize performance across the board.

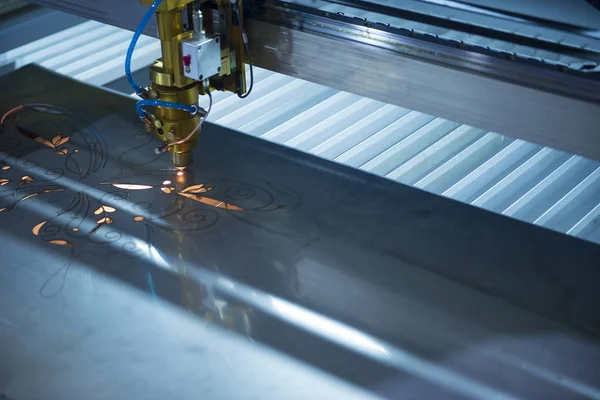

Laser Cutting Systems

Laser cutting has emerged as one of the most versatile and efficient methods of sheet metal fabrication. High-powered lasers can precisely cut through various materials with exceptional speed and accuracy, eliminating the need for tooling changes and reducing material waste. Furthermore, CNC-controlled laser cutting systems enable intricate designs and complex geometries to be produced with ease, opening up new possibilities for product innovation and customization.

CNC Press Brakes

CNC press brakes have revolutionized the process of bending and forming sheet metal components. These machines utilize hydraulic or electric mechanisms to exert precise force on a workpiece, allowing for highly accurate bends and angles to be achieved. Advanced features such as automatic tool changing, angle measurement, and offline programming further enhance productivity and flexibility, enabling manufacturers to produce complex parts with minimal setup time.

Automated Systems Integration

In addition to individual machines, modern sheet metal fabrication facilities often incorporate comprehensive automation and integration systems to optimize workflow and maximize efficiency. Robotic arms, conveyor systems, and material handling equipment work in tandem with CNC machinery to seamlessly transfer workpieces between processes, minimize downtime, and reduce labor costs. Furthermore, sophisticated software solutions provide real-time monitoring, scheduling, and optimization capabilities, enabling operators to fine-tune production parameters for optimal results.

Unlocking the Full Potential

The adoption of modern sheet metal machinery offers numerous benefits for manufacturers looking to stay ahead in today's competitive market. By embracing cutting-edge technology and optimizing their operations, businesses can unlock a host of advantages that drive growth, innovation, and profitability.

Enhanced Productivity and Throughput

One of the primary advantages of modern sheet metal machinery is its ability to significantly increase productivity and throughput. By automating repetitive tasks, minimizing setup times, and maximizing machine utilization, manufacturers can produce more parts in less time, thereby meeting tight deadlines and fulfilling customer demands with ease.

Improved Quality and Precision

Another key benefit of modern sheet metal machinery is its unparalleled precision and quality control capabilities. CNC-driven processes ensure consistency and accuracy across all production runs, virtually eliminating errors, defects, and rework. As a result, manufacturers can deliver high-quality products that meet the most stringent specifications, enhancing customer satisfaction and reputation in the marketplace.

Cost Savings and ROI

While the initial investment in modern sheet metal machinery may seem substantial, the long-term cost savings and return on investment (ROI) can be significant. By reducing labor costs, material waste, and downtime, businesses can achieve greater operational efficiency and profitability over time. Moreover, the ability to produce high-quality parts in-house eliminates the need for outsourcing and reduces lead times, further enhancing cost-effectiveness and competitiveness in the market.

Harnessing Innovation: Advancing Sheet Metal Fabrication

The journey of sheet metal fabrication has been a tale of continuous innovation, driven by the quest for efficiency, precision, and sustainability. As industries evolve and demands shift, manufacturers are compelled to explore new frontiers of technology to remain competitive and meet the ever-changing needs of their customers. In this era of rapid technological advancement, the role of innovation in sheet metal fabrication cannot be overstated.

Embracing Industry 4.0: The Rise of Smart Manufacturing

At the heart of the modern manufacturing revolution lies the concept of Industry 4.0, characterized by the integration of digital technologies into every aspect of the production process. Smart manufacturing systems leverage interconnected sensors, data analytics, and artificial intelligence to optimize operations, improve decision-making, and drive continuous improvement. In the realm of sheet metal fabrication, this means harnessing the power of real-time data insights to enhance efficiency, minimize waste, and maximize productivity.

IoT-enabled Machinery

- Integration of sensors for real-time monitoring of equipment performance.

- Remote diagnostics and predictive maintenance to minimize downtime.

- Optimization of production schedules based on machine utilization data.

Predictive Analytics and Machine Learning

- Analysis of historical data to identify trends and patterns.

- Predictive maintenance algorithms to forecast equipment failures.

- Machine learning models for process optimization and quality control.

20 Fowler Rd, Dandenong South VIC 3175, Australia

Phone : 61397946675